Introduction: Zeolite / MOF Synergy

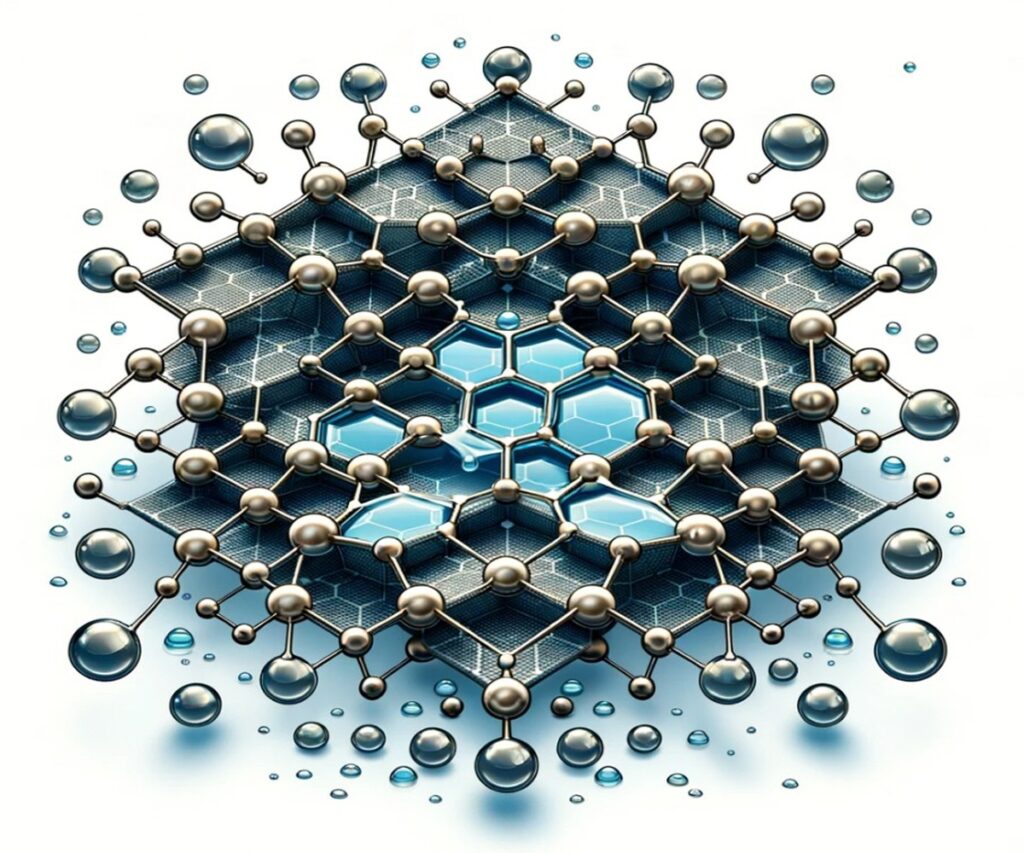

In the quest to design advanced functional materials, scientists have long sought to combine the exceptional properties of zeolites and metal-organic frameworks (MOFs). Zeolites, with their well-defined crystalline structures and uniform micropores, offer unparalleled molecular sieving capabilities. Meanwhile, MOFs, constructed from metal nodes and organic linkers, boast unprecedented structural diversity and tunability. However, achieving a seamless integration of these two distinct classes of porous materials has remained a formidable challenge until now.

This pioneering research unveils a groundbreaking synthetic approach that enables the assembly of ultra-complex, hierarchically porous MOFs seamlessly integrated with preformed zeolitic subnetworks. By harnessing the synergy between zeolites and MOFs, this innovative technology could unlock a new frontier in materials design, revolutionizing various fields through its unique structural features and synergistic properties.

Zeolites, crystalline aluminosilicates with uniform micropores (< 2nm) and high surface areas, have long been workhorses in catalysis, separation, and ion exchange processes. However, their structural complexity is inherently limited by the available molecular building blocks used in their synthesis.

In contrast, MOFs, constructed from metal nodes and organic linkers through coordination bonds, offer an unprecedented level of structural and chemical diversity. By carefully selecting the metal nodes and organic linkers, scientists can finely tune the pore sizes, shapes, and chemical environments within MOFs. However, many MOFs lack the long-range crystalline order found in zeolites, which can be essential for certain applications.

The ability to integrate preformed zeolitic subnetworks within the MOF architecture could potentially yield advanced materials that combine the crystallinity and molecular sieving capabilities of zeolites with the structural complexity and tunability of MOFs.

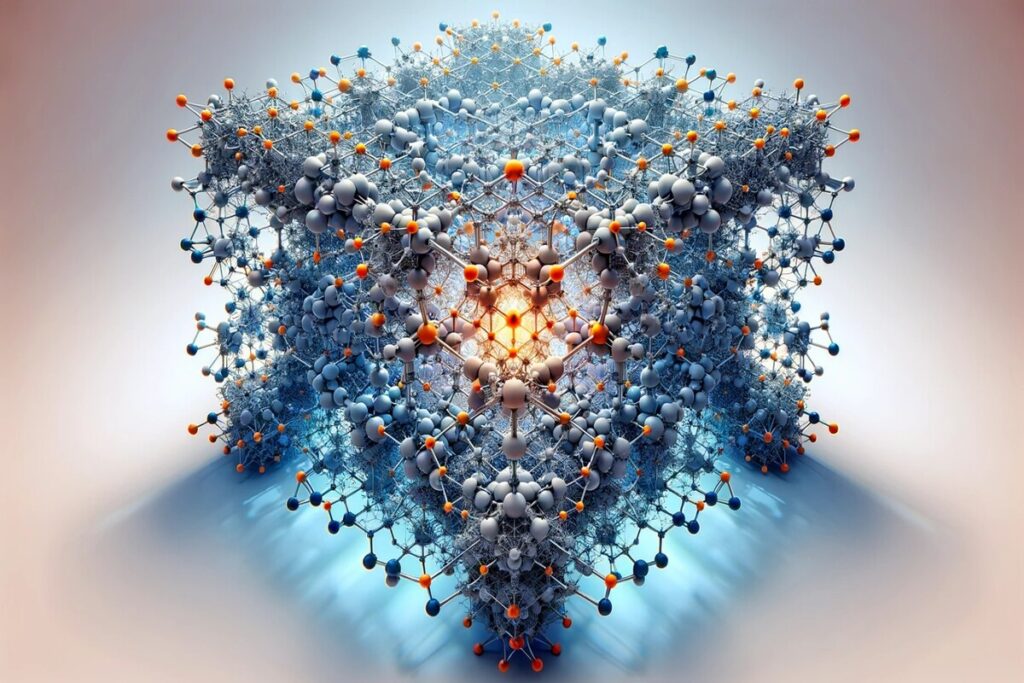

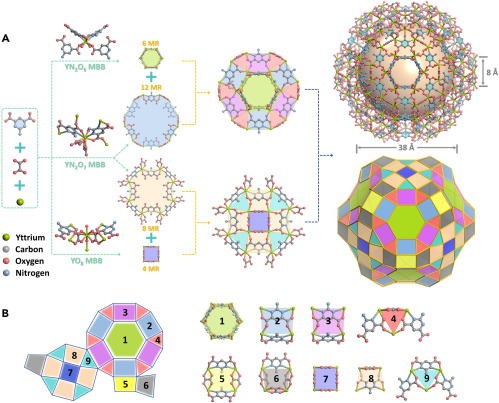

The key to this groundbreaking assembly strategy lies in the use of molecular building blocks (MBBs) as larger secondary building units (SBUs). The synthetic process involves several intricate steps:

- Synthesis of MBBs with specific geometries and functionalities tailored for the desired MOF structure.

- Careful selection of metal nodes and organic linkers that can form strong coordination bonds with the MBBs.

- Controlled self-assembly of MBBs, metal nodes, and organic linkers into an extended 3D network through coordination bonds.

- Precise integration of preformed zeolitic subnetworks within the MOF architecture during the self-assembly process.

Advanced characterization techniques, such as X-ray diffraction, gas sorption analysis, spectroscopic methods, and high-resolution microscopy, are employed to elucidate the intricate porous structures formed and confirm the successful integration of zeolitic subnetworks.

Zeolite Assembly Technology:

This bottom-up, modular approach enables the rational design of MOFs with unprecedented structural complexity and hierarchical porosity spanning the micro-, meso-, and macroporous regimes. By judiciously selecting the MBB geometries, metal nodes, organic linkers, and zeolitic subnetworks used in the assembly process, the resulting materials can be precisely tailored to meet specific application requirements.

The incorporation of preformed zeolitic subnetworks within the MOF architecture imparts exceptional molecular sieving capabilities from the uniform micropores of zeolites. Simultaneously, the inherent structural diversity of MOFs is preserved, allowing for the fine-tuning of pore sizes, shapes, and chemical environments to achieve desired functionalities. This synergistic integration of zeolitic subnetworks and MOF architectures could potentially overcome the limitations of traditional porous materials, paving the way for the development of advanced functional materials with unprecedented properties and performance.

Crucially, this modular assembly strategy allows for an unprecedented level of control over the structural features and properties of the resulting materials. By carefully selecting the molecular building blocks, their geometries, and the integrated zeolitic components, researchers can engineer materials with tailored pore architectures, ranging from microporous to mesoporous and even macroporous domains. This hierarchical porosity can facilitate efficient mass transport and diffusion of reactants, products, and target molecules, enhancing the materials’ performance in various applications.

Furthermore, the ability to integrate preformed zeolitic subnetworks with well-defined crystalline structures opens up new avenues for precise active site engineering. The uniform micropores of zeolites can act as shape-selective catalytic pockets, while the MOF components can introduce additional catalytic centers or provide tunable chemical environments. This synergy between the two distinct porous systems could lead to unprecedented catalytic activities, selectivities, and stabilities, enabling the development of highly efficient heterogeneous catalysts for a wide range of chemical transformations.

Moreover, the modular nature of this assembly strategy allows for the incorporation of various functional groups, metals, or guest molecules within the porous frameworks. This versatility enables the design of materials with tailored physicochemical properties, such as optical, electronic, magnetic, or responsive characteristics, unlocking new possibilities in fields like sensing, optoelectronics, energy storage, and stimuli-responsive systems.

By leveraging the synergy between zeolites and MOFs through this ingenious assembly technology, researchers can create advanced functional materials with precisely engineered porous architectures, tailored active sites, and synergistic properties. This versatile platform provides an unprecedented opportunity to design materials for addressing global challenges in energy, environment, healthcare, and advanced technologies, pushing the boundaries of materials science and engineering.

Prospects and Applications:

The ability to rationally design and construct ultra-complex, hierarchically porous MOFs integrated with zeolitic subnetworks opens up an expansive world of possibilities across various fields:

- Energy and Environment:

Highly selective gas storage and separation systems with exceptional capacity, selectivity and energy efficiency for carbon capture, natural gas purification, hydrogen storage and more. Tunable heterogeneous catalysts with precisely engineered active sites for sustainable chemical transformations, energy conversion processes like fuel cells, electrolyzers, and photocatalytic systems. Membrane separations leveraging the synergistic molecular sieving of zeolites and MOFs for energy-efficient gas and liquid separations. Electrical energy storage systems like metal-air batteries and supercapacitors utilizing the high surface area and redox activity. - Healthcare and Biotechnology:

Tailored drug delivery platforms with finely tunable release kinetics, targeting capabilities and stimuli-responsiveness for enhanced therapeutic efficacy and reduced side effects. Innovative biosensing and biodiagnostic devices by immobilizing a wide range of biomolecules in the designed porous environment for early and accurate disease detection. Protein crystallography and structure determination leveraging the highly ordered porous networks as crystallization matrices for drug discovery and design. Enzyme immobilization and biocatalysis by providing tailored microenvironments that enhance enzyme stability and activity for industrial biocatalytic processes. - Electronics and Optoelectronics:

Multifunctional materials for next-generation electronic and optoelectronic devices like solar cells, LEDs, lasers, photodetectors by integrating semiconductor properties. Molecular electronics leveraging the well-defined porous architectures for molecular wiring, switching, data storage and quantum computing components. Chemical sensors and optoelectronic sensing platforms by incorporating probe molecules within the designed microenvironments. - Catalysis and Separations:

Unprecedented catalytic performance by synergistically combining the advantages of zeolites (shape selectivity, acidity) and MOFs (tunability, functionality). Tandem catalytic systems by integrating multiple catalytic sites of different nature within a single porous material. Advanced adsorbents and membranes for efficient removal of pollutants, recovery of valuable products and molecular separations by exploiting the hierarchical porosity.

By integrating zeolitic subnetworks, this versatile materials platform provides an unprecedented opportunity to construct tailored porous architectures with finely tuned structural features and synergistic properties. This could enable breakthrough materials for addressing global challenges in energy, environment, healthcare, and advanced technologies.

Conclusion: Ingenious Assembly Technology Zeolite/MOF

This groundbreaking research presents a paradigm shift in materials design by seamlessly integrating the distinct advantages of zeolites and metal-organic frameworks (MOFs) through an ingenious modular assembly strategy utilizing molecular building blocks. The resulting ultra-complex, hierarchically porous materials with embedded zeolitic subnetworks could unlock revolutionary capabilities by merging the crystallinity of zeolites with the structural complexity and tunability of MOFs.

By leveraging the synergistic effects of these two distinct classes of porous materials, this innovative technology enables the rational construction of tailored porous architectures with unprecedented structural features and synergistic properties. The materials can be precisely engineered by judicious selection of molecular building block geometries, metal nodes, organic linkers, and integrated zeolitic components, allowing for the fine-tuning of pore sizes, shapes, chemical environments, and catalytic functionalities.

This versatile assembly platform paves the way for the development of next-generation functional materials that could revolutionize numerous fields through their unique capabilities. For instance, in the realm of energy and environment, these materials could enable highly selective gas storage and separation systems, efficient heterogeneous catalysts for sustainable chemical processes, and advanced membrane separations. Additionally, in healthcare and biotechnology, they could facilitate controlled drug delivery, innovative biosensing platforms, enhanced protein crystallography techniques, and tailored biocatalytic systems.

Furthermore, the well-defined porous architectures could find applications in molecular electronics, optoelectronics, chemical sensing, and quantum computing components. The synergistic integration of zeolitic and MOF attributes could also lead to unprecedented catalytic performance, tandem catalytic systems, and advanced adsorbents for efficient molecular separations and purifications.

By unlocking the synergistic potential of zeolites and MOFs, this groundbreaking assembly technology provides an unparalleled opportunity to design advanced functional materials with tailored architectures and properties, addressing global challenges in energy, environment, healthcare, and cutting-edge technologies. The ability to rationally engineer these materials at the molecular level opens up new frontiers in materials science, paving the way for innovative solutions to some of the world’s most pressing issues.

Source: Li, Jiantang, et al. “Using small building blocks to assemble ultra-complex, multifaceted metal-organic frameworks with zeolitic, mesoporous subnetwork.” Chem 10.2 (2024): 567-577.

https://www.cell.com/chem/fulltext/S2451-9294(23)00481-3

※ This report has been compiled for the purpose of providing general information. It is based on data gathered by CHEMiFORGE. Should you have any inquiries or need to make decisions based on this report, it is advisable to consult with a CHEMiFORGE.