Introduction : Sol Gel Process

Sol gel processing, a versatile method for synthesizing materials at low temperatures, has become a staple in material science. It is used to produce ceramics, hybrid materials, thin films, special glasses, bio-active glasses, and complex shapes. Sol-gel chemistry has also evolved into a valuable tool for synthesizing nanomaterials, surface modifying materials, and creating high-purity materials.

Steps in the Sol Gel Process

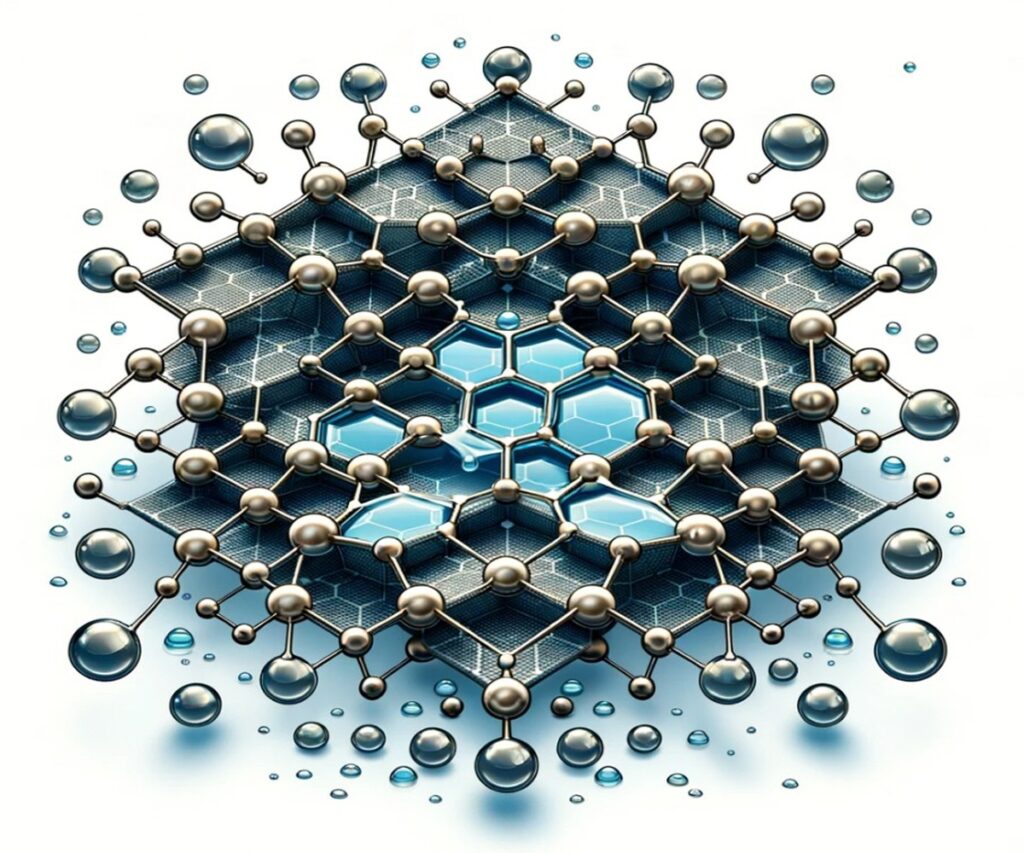

1. Hydrolysis and Polymerization: The precursor, which is usually a metal alkoxide, reacts with water in a hydrolysis reaction. The hydrolysis is followed by a polymerization process, where monomers (the hydrolyzed precursors) condense to form oligomers and then polymers in the form of a three-dimensional network.

2. Gelation: As the polymerization reaction proceeds, the viscosity of the sol increases until a gel is formed. This gel is a rigid network filled with solvent, which constitutes the continuous phase.

3. Aging: The gel is then left to age, allowing the growth of the polymer chains and strengthening of the gel network.

4. Drying: After aging, the solvent is removed from the gel, usually by evaporation, leading to a dried gel or ‘xerogel’. If the drying is performed under supercritical conditions, an ‘aerogel’ is obtained.

5. Densification and Dehydroxylation: Upon further heat treatment, densification occurs where the gel shrinks and becomes more compact. Dehydroxylation, the loss of hydroxyl groups, also occurs at this stage, leading to the formation of a more stable oxide network.

6. Crystallization or Vitrification: Depending on the temperature and the nature of the material, the amorphous network can either crystallize into a specific structure or transform into a glassy, non-crystalline state.

Initially, sol gel methods were explored for their potential in creating bulk gels and oxides as an alternative to high-temperature glass formation. However, the focus has shifted due to the high costs and environmental impacts associated with solvent use. Today, the sol-gel process is revered for its versatility in thin film fabrication and its role in the glass industry, particularly for architectural applications.

Sol gel chemistry has evolved from a specific study subject to a widely used tool for synthesizing nanomaterials. The development of new alkoxides and organosilanes has expanded the applications of sol-gel chemistry, including surface modification techniques like silanization. The process’s adaptability has led to its integration into various fields, including the nuclear industry, due to the high purity of the materials produced.

Sol gel processing is compatible with advanced manufacturing methods like 3D printing, enabling the creation of complex shapes essential for tissue regeneration scaffolds and other applications. It has also been instrumental in synthesizing hybrid organic-inorganic materials, such as contact lenses and functional nanocomposites.

The sol gel technique has been instrumental in synthesizing hybrid organic-inorganic materials. These materials, characterized by a covalent bond between silicon and carbon, have found extensive industrial applications ranging from contact lenses to functional nanocomposites.

Polyhedral oligomeric silsesquioxanes (POSS) represent a unique class of nanomaterials derived from sol-gel chemistry. Their ability to be easily functionalized has opened up new applications in various fields, including solar cells and sunscreens.

The synthesis of meso-porous materials is a significant outcome of combining supramolecular chemistry with sol-gel techniques. These materials have vast applications in healthcare, catalysis, and photonic technologies, with ongoing research focused on bio-nanotechnology.

Conclusion

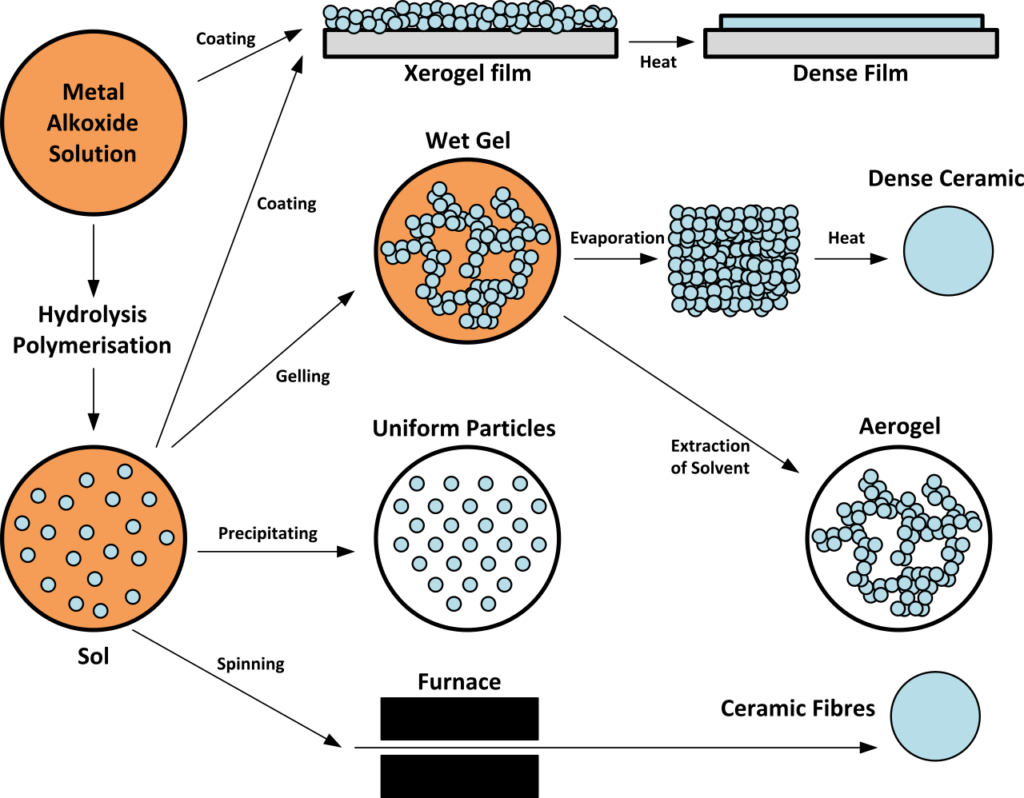

Aerogel, one of the most successful commercial products of sol gel technology, is known for its light weight and large surface area. It is used in a variety of industries including aerospace, electronics, and construction. However, commercialization of Aerogel manufactured through the sol-gel process is slow. The reason is that the manufacturing cost is high and durability needs to be improved. Addressing these challenges requires ongoing research and development to find cost-effective production methods, improve the mechanical properties of aerogels, and develop new applications that can justify the higher costs associated with these materials.

Sol gel processing has paved the way for numerous advancements in material science and technology. The future challenges lie in reducing environmental impact and developing biocompatible functional materials, with endless possibilities on the horizon.

Source: Innocenzi, P. (2023). Sol gel processing for advanced ceramics, a perspective. Open Ceramics, 100477.

https://doi.org/10.1016/j.oceram.2023.100477

※ This report has been compiled for the purpose of providing general information. It is based on data gathered by CHEMiFORGE. Should you have any inquiries or need to make decisions based on this report, it is advisable to consult with a CHEMiFORGE.