Introduction: EMI Shielding Material

EMI (Electromagnetic Interference) shielding is crucial in protecting electronic devices from electromagnetic radiation emitted by various sources. It works by reflecting and absorbing electromagnetic waves, preventing them from interfering with the operation of sensitive electronic components. The efficiency of this EMI shielding is measured by Shielding Effectiveness (SE) or Shielding Efficiency (SE).

The EMI shielding process involves several mechanisms, including reflection loss at the air-shield interface, absorption loss within the shielding material itself, and multiple reflection losses, which become more significant in thinner shields. The material’s intrinsic properties, such as electrical conductivity, permeability, and thickness, play a significant role in determining its EMI shielding effectiveness.

Highly conductive materials, like metals, are excellent at reflecting electromagnetic waves due to their mobile charge carriers, which interact with the incident electromagnetic fields. However, absorption losses are also crucial for attenuating the transmitted wave, especially at higher frequencies. EMI shielding materials must strike a balance between reflection and absorption properties to achieve optimal shielding performance across a wide range of frequencies.

Thesis – Design and advanced manufacturing of electromagnetic interference shielding materials

https://www.sciencedirect.com/science/article/pii/S1369702123000846

This content was produced with Typecast, an AI virtual actor service – Characters casted: Tyson

This video supports English/Korean subtitles. (YouTube subtitle settings)

Sources – Dall-E

VIDEO LINK

Conclusion

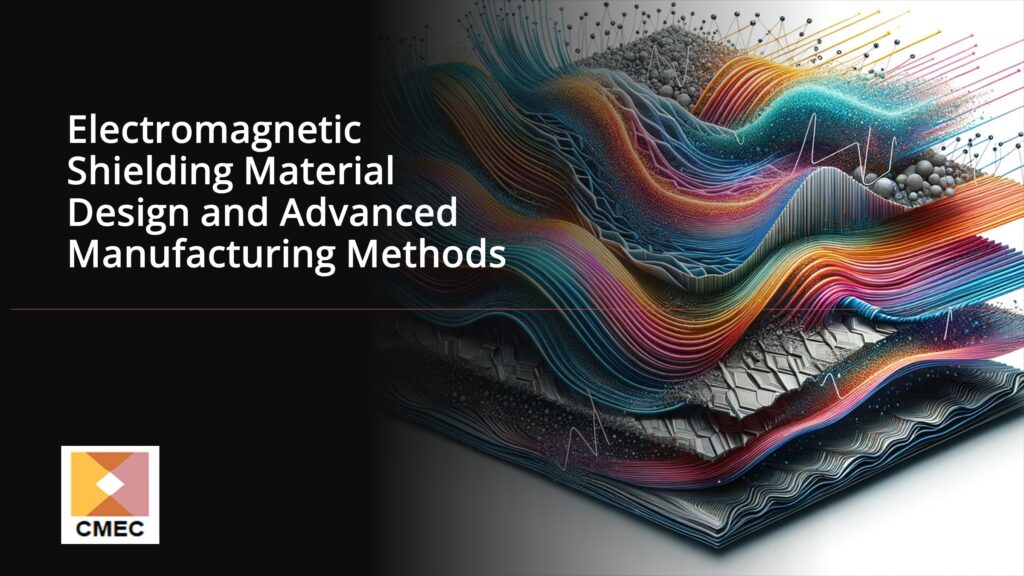

Effective electromagnetic interference shielding is essential for the proper functioning of electronic devices and systems in an environment where electromagnetic radiation is increasingly prevalent. By understanding the mechanisms involved in the electromagnetic interference shielding process, such as reflection, absorption, and multiple reflections, researchers and engineers can develop innovative materials and designs tailored to meet the specific shielding requirements of various applications.

The choice of shielding material is critical, as it must possess the right combination of properties, including high conductivity, permeability, and appropriate thickness, to maximize shielding effectiveness. While traditional materials like metals have been widely used, ongoing research is exploring advanced materials, such as carbon-based nanomaterials, metallic foams, and conductive polymers, to address the ever-increasing demand for lightweight, flexible, and high-performance electromagnetic interference shielding solutions.

As electronic devices become more compact and complex, the need for effective electromagnetic interference shielding will continue to grow, driving further innovation in materials science, engineering, and manufacturing processes. Interdisciplinary collaborations between researchers, industry partners, and regulatory bodies will be crucial in addressing the challenges of electromagnetic interference shielding and ensuring the reliable operation of electronic systems in various environments.

※ This report has been compiled for the purpose of providing general information. It is based on data gathered by CHEMiFORGE. Should you have any inquiries or need to make decisions based on this report, it is advisable to consult with a CHEMiFORGE.