Introduction : Core Shell Structure

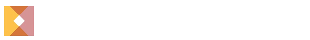

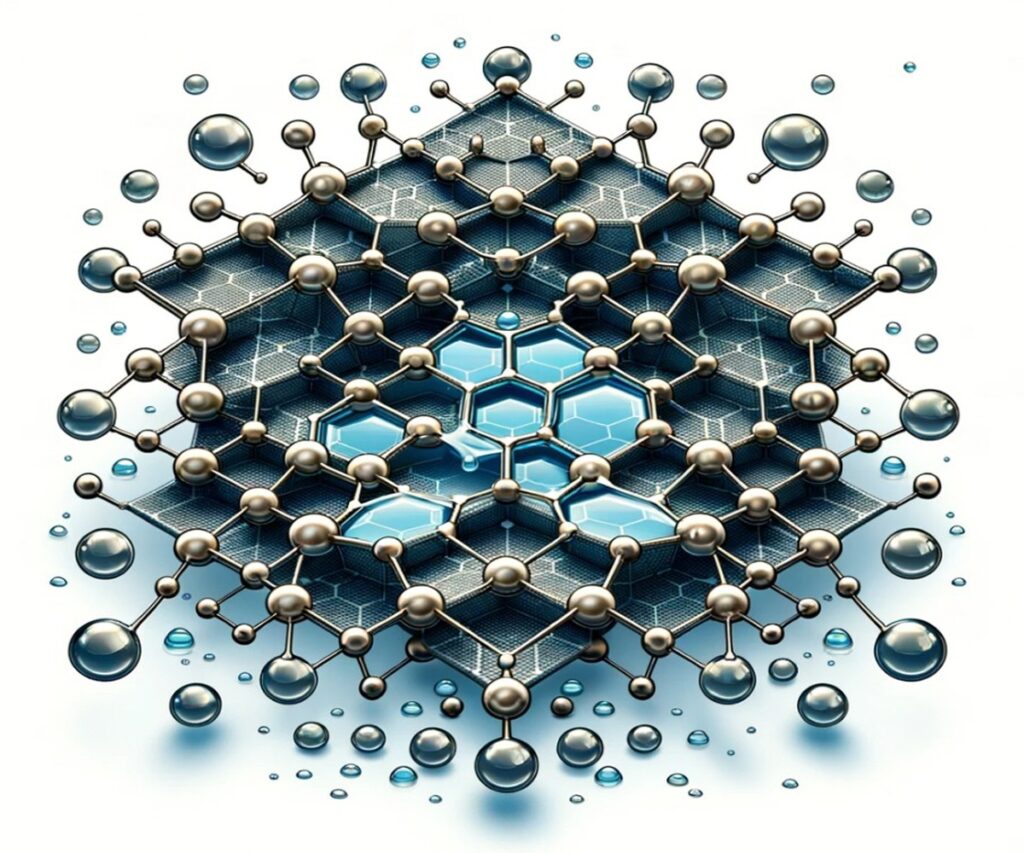

Core shell structures are an important innovation in materials science, enabling the combination of two or more materials to exhibit unique properties. This structure combines the properties of the core (the inner material) and the shell (the outer coating material) to provide enhanced or new functionality. The core material is chosen for a specific property (e.g., magnetic, optical, structural), and the shell material is chosen for protection, functionalization or interaction with a specific environment.

There are a variety of methods for synthesizing core shell structures. Some of the most common methods include:

- Liquid coating: This method involves the use of a coating precursor to form a thin, uniform shell layer on the core material. The coating precursor is typically a solution of the shell material in a solvent. The core material is then dipped or sprayed with the coating precursor solution, and the solvent is allowed to evaporate.

- Infiltration: This method involves the infiltration of a coating precursor into the pores of the core material. The coating precursor is then oxidized or reduced to form the shell material. Infiltration is a common method for synthesizing core-shell structures with metal cores.

- Metal alkoxide process: This method involves the hydrolysis and condensation of metal alkoxides to form a variety of complex metal oxide coating precursors. The coating precursor can then be used to coat a variety of core materials, including metals, metal oxides, and polymers.

- Spray coating: This method involves spraying a coating precursor solution onto the core material. The coating precursor is then allowed to dry and form a shell layer. Spray coating is a common method for synthesizing core-shell structures with submicron-sized core materials.

The choice of synthesis method depends on the desired properties of the core shell structure. For example, liquid coating is a good choice for synthesizing core-shell structures with a uniform shell layer, while infiltration is a good choice for synthesizing core-shell structures with metal cores.

Properties of core shell structures

Core-shell structures exhibit a variety of properties that are not found in either the core or shell material alone. These properties are due to the combination of the two materials and the unique interface between them.

Some of the key properties of core-shell structures include:

- Protection: The shell can protect the core from degradation or damage. For example, a metal oxide shell can protect a metal core from corrosion.

- Modification: The shell can modify the properties of the core. For example, a silica shell can improve the solubility of a drug.

- Functionality: The shell can provide new functionality to the core. For example, a semiconductor shell can enable photoluminescence.

Applications of core shell structures

Core shell structures have a wide range of applications in a variety of fields. Some of the most common applications include:

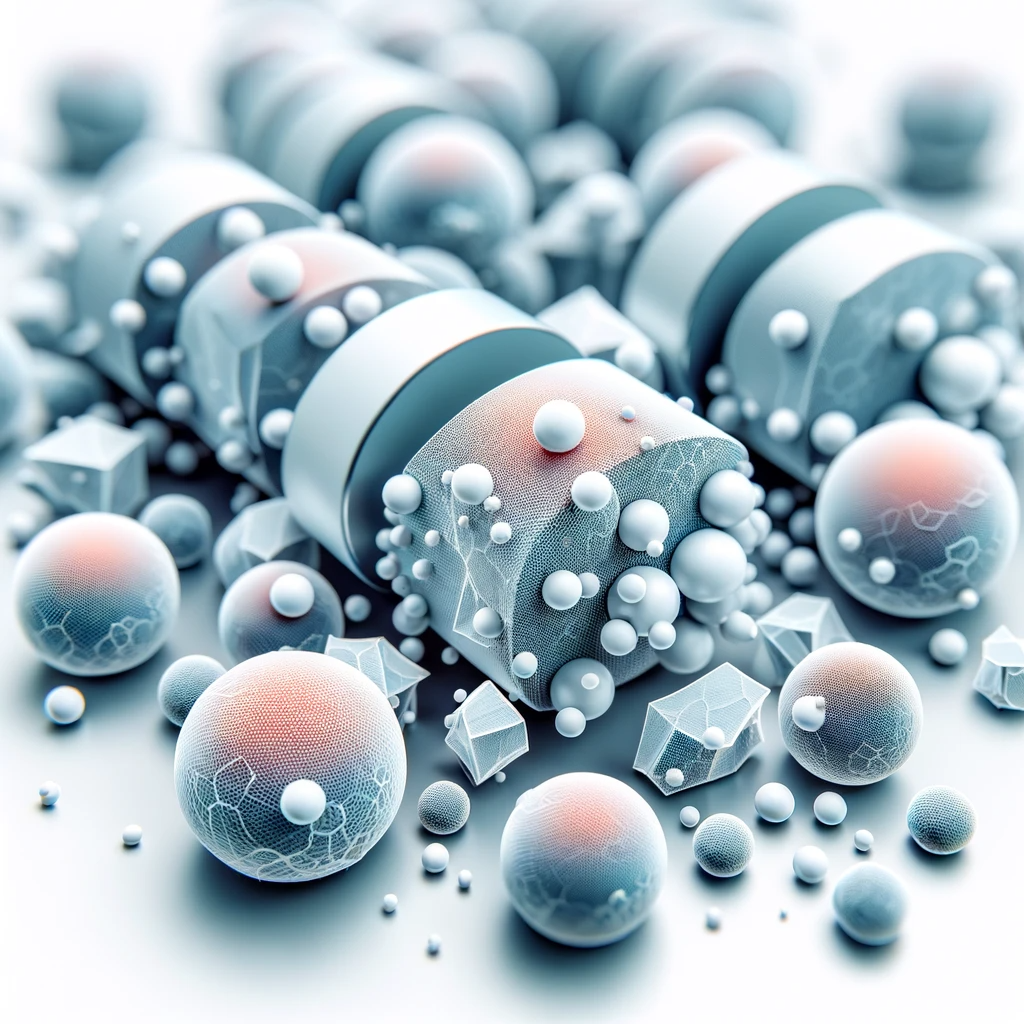

- Electronics and energy: Core shell structures are used in batteries, solar cells, and semiconductors.

- Catalysis: Core shell structures are used to improve the efficiency and selectivity of chemical reactions.

- Biomedical: Core shell structures are used in drug delivery, imaging, and therapeutics.

- Optical materials: Core shell structures are used in LEDs, lasers, and optical sensors.

Core shell structures are a versatile class of materials that exhibit a variety of properties and applications. Their unique properties are derived from the combination of two materials and the unique interface between them. This combination of properties makes core-shell structures promising materials for a wide range of applications.

The specific choice of core and shell materials depends on the desired properties and applications. For example, a metal core can provide electrical conductivity, while a semiconductor shell can provide optical properties. The specific interface between the core and shell can also be tailored to achieve desired properties.

Core shell structures have already found a wide range of applications in electronics, energy, catalysis, and biomedical applications. As research in this area continues, new and innovative applications are being developed all the time.

Source: Ohno, Tomoya, et al. “Coating on a primary particle by wet process to obtain core-shell structure and their application.” Advanced Powder Technology 34.12 (2023): 104247.

https://doi.org/10.1016/j.apt.2023.104247

※ This report has been compiled for the purpose of providing general information. It is based on data gathered by CHEMiFORGE. Should you have any inquiries or need to make decisions based on this report, it is advisable to consult with a CHEMiFORGE.