Introduction: Carbon Fiber Composite

In the realm of materials science, two significant developments are setting the stage for a more sustainable and efficient future. Hyosung’s product expansion through the application of sustainable carbon fiber and Teijin’s innovative approach to producing carbon fiber composite from sustainable raw materials represent a pivotal change in the industry.

The recent plane crash in Tokyo has brought carbon fiber composite into the spotlight, raising questions about their safety and reliability. As investigations proceed, the incident serves as a reminder of the importance of rigorous testing and quality control in the use of advanced materials. It also highlights the need for continuous improvement and innovation to ensure the safety and performance of carbon fiber in high-stakes applications.

Hyosung’s Sustainable Carbon Fiber Expansion

Hyosung, a leading innovator in the textiles industry, has recently broadened its range of certified sustainable carbon fibers. This move not only underscores the company’s commitment to environmental stewardship but also meets the growing demand for eco-friendly materials in the fashion and textiles industry. By leveraging advanced technologies, Hyosung aims to reduce the environmental footprint of its products while maintaining their high-quality and performance standards.

Toray’s Breakthrough in Carbon Fiber Technology

Toray Industries has made headlines with its development of a new carbon fiber that is both stronger and lighter than its predecessors. This breakthrough promises to revolutionize industries by offering materials that enhance performance while minimizing weight, a critical factor in the automotive and aerospace sectors. Toray’s innovation aligns with the industry’s push towards more efficient and sustainable materials.

Teijin’s Sustainable Carbon Fiber Production

Teijin has announced its initiative to produce carbon fiber using sustainable raw materials, marking a significant step forward in the industry’s sustainability efforts. This approach not only reduces the environmental impact of carbon fiber production but also sets a new standard for the integration of eco-friendly practices in the manufacturing process. Teijin’s commitment to sustainability is expected to influence other players in the industry to adopt greener practices.

Conclusion

The advancements in sustainable technology of carbon fiber composite represent a convergence of innovation, sustainability, and performance. As the industry moves forward, companies like Hyosung, Toray, and Teijin are leading the charge in creating carbon fiber composite that are not only environmentally friendly but also enhance the capabilities and safety of products across various sectors. The ongoing scrutiny and development in these areas underscore the importance of materials science in shaping a sustainable and technologically advanced future.

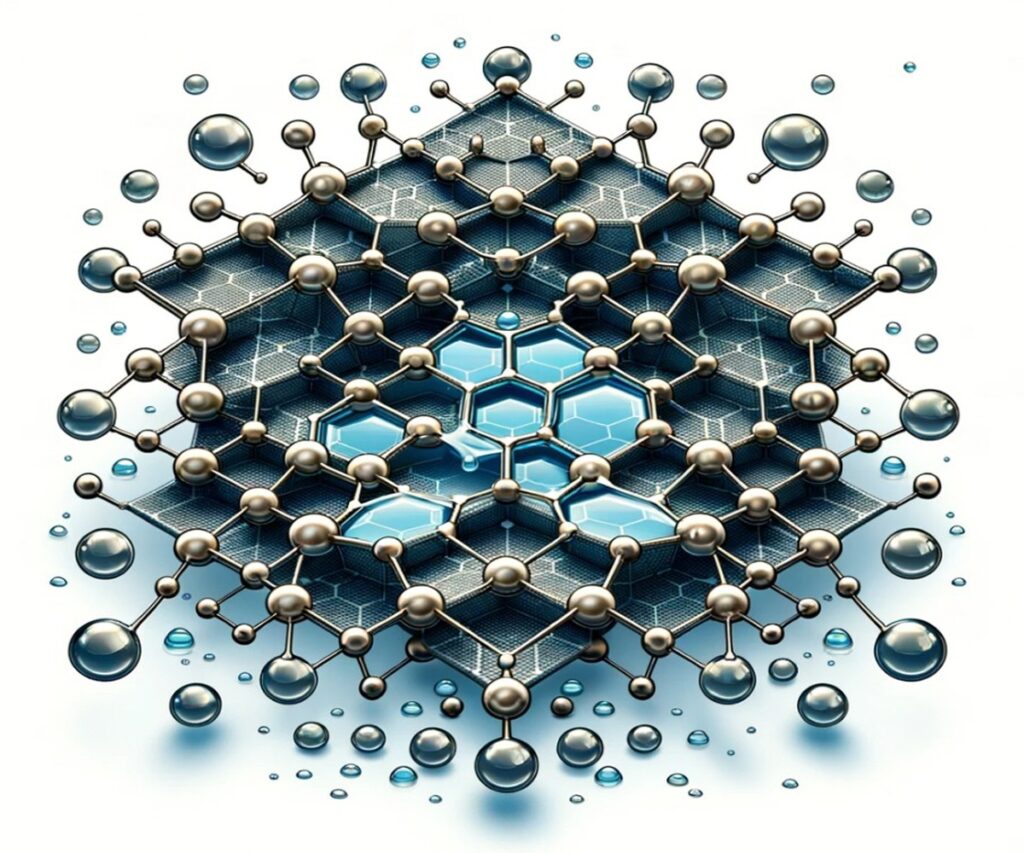

Carbon fiber composite offer a unique combination of strength, lightweight, and durability, making them ideal for a wide range of applications. In the automotive industry, carbon composite components can significantly reduce vehicle weight, leading to improved fuel efficiency and lower carbon emissions. Similarly, in the aerospace sector, carbon composites are being increasingly utilized to manufacture lighter and more fuel-efficient aircraft, contributing to a more sustainable aviation industry.

The development of carbon fiber composite is not limited to traditional industries; they are also making inroads into emerging technologies. For instance, in the renewable energy sector, carbon fiber composite blades are being used in wind turbines, enhancing their performance and longevity. Additionally, carbon fiber composite is being explored for use in hydrogen storage tanks, facilitating the transition towards a hydrogen-based economy.

However, the true potential of carbon fiber composite lies in their sustainability. Unlike traditional materials, carbon fiber composite can be recycled and repurposed, reducing waste and promoting a circular economy. Various companies are investing in research and development to improve the recyclability and eco-friendly production processes of carbon fiber composite, further solidifying their position as a sustainable material of the future.

Moreover, carbon fiber composite offers unique opportunities for innovation and customization. By tailoring the composition and manufacturing processes, researchers can create carbon composites with specific properties, such as enhanced thermal or electrical conductivity, making them suitable for a wide range of applications, from electronics to construction.

As the demand for sustainable and high-performance materials continues to grow, carbon composites are poised to play a crucial role in shaping the future of various industries. With ongoing advancements in carbon composite technology, companies like Hyosung, Toray, and Teijin are well-positioned to lead the charge towards a more sustainable and technologically advanced world.

Source:

1) Stronger and lighter Toray carbon, January 22 2024 – https://www.innovationintextiles.com/stronger-and-lighter-toray-carbon/

2) Tokyo plane crash puts carbon fiber materials under scrutiny, January 8 2024 – https://asia.nikkei.com/Spotlight/Japan-plane-crash/Tokyo-plane-crash-puts-carbon-fiber-materials-under-scrutiny

3) Hyosung expands its certified sustainable solution offer, January 18 2024 – https://blog.hyosungtnc.com/hyosung-furthers-its-certified-sustainable-denim-textile-and-sourcing-solutions/

4) Teijin to Produce Carbon Fiber from Sustainable Raw Materials, January 24 2024 – https://www.plasticstoday.com/automotive-mobility/teijin-to-produce-carbon-fiber-from-sustainable-raw-materials

※ This report has been compiled for the purpose of providing general information. It is based on data gathered by CHEMiFORGE. Should you have any inquiries or need to make decisions based on this report, it is advisable to consult with a CHEMiFORGE.