Introduction: hydrogen Storage with Aluminum MOF

Hydrogen is a clean-burning fuel that has the potential to replace fossil fuels in a variety of applications. However, hydrogen is difficult to store because it is a gas and takes up a lot of volume.

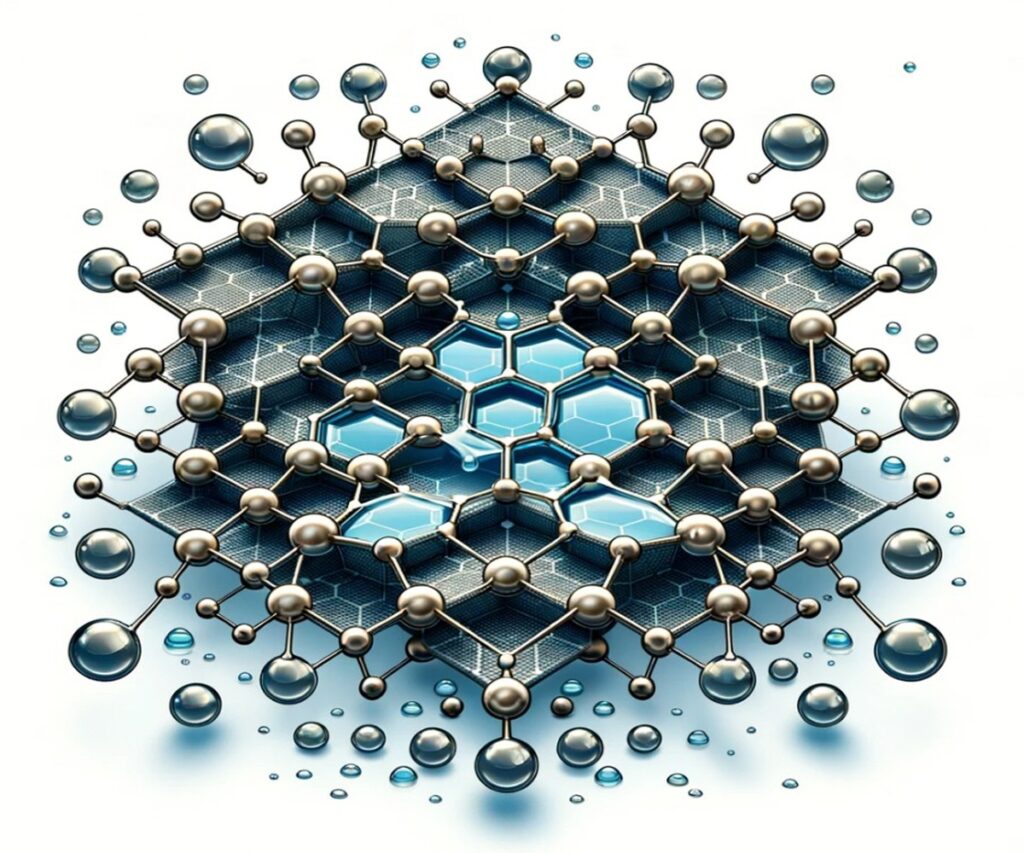

Metal-organic frameworks (MOF) are a promising new material for hydrogen storage. MOF are porous solids that can trap hydrogen molecules in their pores. MOF are made up of metal atoms and organic linkers, which are carbon-based molecular chains. The metal atoms serve as hubs that are tied together with the organic linkers. The result is a chemical cage with passageways and voids that trap gases injected under mild pressures. When the pressure is lifted, the hydrogen flows back out.

In a recent paper published in the Journal of the American Chemical Society (JACS), researchers at the University of California, Santa Barbara (UCSB) and the National Institute of Standards and Technology (NIST) reported on a new aluminum-based MOF that shows promise for hydrogen storage. The Aluminum MOFs is inexpensive and can store significant amounts of hydrogen at low pressures.

The researchers tested the Aluminum MOF for hydrogen storage and found that it could store up to 15 kilograms of hydrogen per cubic meter at a pressure of just 10 bar. This is about two-thirds as much hydrogen as the best nickel-based MOFs can store, but it is much less expensive. The Aluminum MOF also has a binding energy of just 8.6 kilojoules per mole of hydrogen, which means that it can release hydrogen easily at room temperature.

The researchers believe that the Aluminum MOF could be used to store hydrogen for backup power sources at industrial operations, such as data centers. The Aluminum MOF is inexpensive and can be operated at low pressures, making it a practical solution for these applications.

The researchers are also working on tweaking the structure of the aluminum MOF to see if they can increase its hydrogen storage capacity. They are also exploring other metal-based MOF for hydrogen storage.

MOFs are a promising new material for hydrogen storage. They are inexpensive, can store significant amounts of hydrogen at low pressures, and can release hydrogen easily at room temperature. MOFs could revolutionize the way we store and transport hydrogen, making it a more viable fuel for a variety of applications.

Here are some of the key benefits of using Aluminum MOF for hydrogen storage:

- Low cost: Aluminum is a relatively inexpensive metal, making Aluminum-MOF a cost-effective solution for hydrogen storage.

- Low operating pressures: Aluminum-MOF can store significant amounts of hydrogen at low pressures, which makes them safer and easier to operate than high-pressure hydrogen storage systems.

- Mild cooling requirement: Aluminum-MOF can release hydrogen easily at room temperature, but they can be cooled slightly to increase their hydrogen storage capacity.

- Scalability: Aluminum-MOF can be produced in large quantities, making them a practical solution for commercial applications.

Potential applications for Aluminum MOF in hydrogen storage:

- Backup power sources: Aluminum-MOF could be used to store hydrogen for backup power sources at industrial operations, such as data centers. This would help to reduce reliance on diesel generators and other fossil fuel-powered backup systems.

- Hydrogen transportation: Aluminu- MOF could be used to transport hydrogen in a safe and efficient manner. This would make it easier to transport hydrogen to remote areas or to locations where there is no access to a natural gas pipeline.

- Portable hydrogen storage: Aluminum-MOF could be used to develop portable hydrogen storage systems for applications such as fuel cell vehicles and drones.

Conclusion – Aluminum MOF for Hydrogen Storage

Overall, Aluminum MOF is a promising new class of materials for hydrogen storage applications. These innovative porous solids offer a multitude of advantages over traditional hydrogen storage technologies, rendering them highly attractive candidates for future development and widespread implementation.

Notably, Aluminum MOF stand out due to their relatively low production costs, facilitated by the abundant availability and inexpensive nature of aluminum precursors. This cost-effectiveness is a pivotal factor in enabling the large-scale deployment of hydrogen storage systems, a crucial prerequisite for the widespread adoption of hydrogen as a clean energy carrier.

Furthermore, Aluminum MOF exhibit exceptional hydrogen uptake capabilities at remarkably low operating pressures, circumventing the need for high-pressure compression systems that often pose significant safety concerns and incur substantial energy penalties.

This unique feature allows for more efficient and streamlined hydrogen storage and delivery processes, reducing the overall system complexity and associated costs. Additionally, the mild cooling requirements for Aluminum MOF, typically involving modest temperature reductions to cryogenic or near-ambient conditions, further contribute to the energy efficiency and practical viability of these materials in real-world applications.

Another key advantage of Al MOFs lies in their inherent scalability, attributed to the well-established synthetic procedures and the ability to tailor their structural properties and performance characteristics through judicious chemical design.

This versatility enables the creation of application-specific Aluminum MOF materials optimized for diverse hydrogen storage scenarios, spanning stationary systems for energy storage to mobile applications in the transportation sector. Moreover, the modular nature of Al MOFs facilitates the seamless integration of these materials into existing infrastructure, minimizing the need for disruptive and costly overhauls.

Collectively, these attributes position Aluminum MOF as a revolutionary advancement in the field of hydrogen storage technology. Their potential to revolutionize the way we store, transport, and utilize hydrogen as a clean and sustainable fuel could have far-reaching implications, paving the way for a more sustainable energy future across a multitude of industries and applications.

The continued research and development efforts in this domain hold promise for overcoming the remaining technical hurdles and unlocking the full potential of Aluminum MOF, thereby contributing to the realization of a hydrogen-based economy.

Source: Chemical cages could store hydrogen, expand use of clean-burning fuel, SCIENCE NEWS

※ This report has been compiled for the purpose of providing general information. It is based on data gathered by CHEMiFORGE. Should you have any inquiries or need to make decisions based on this report, it is advisable to consult with a CHEMiFORGE.